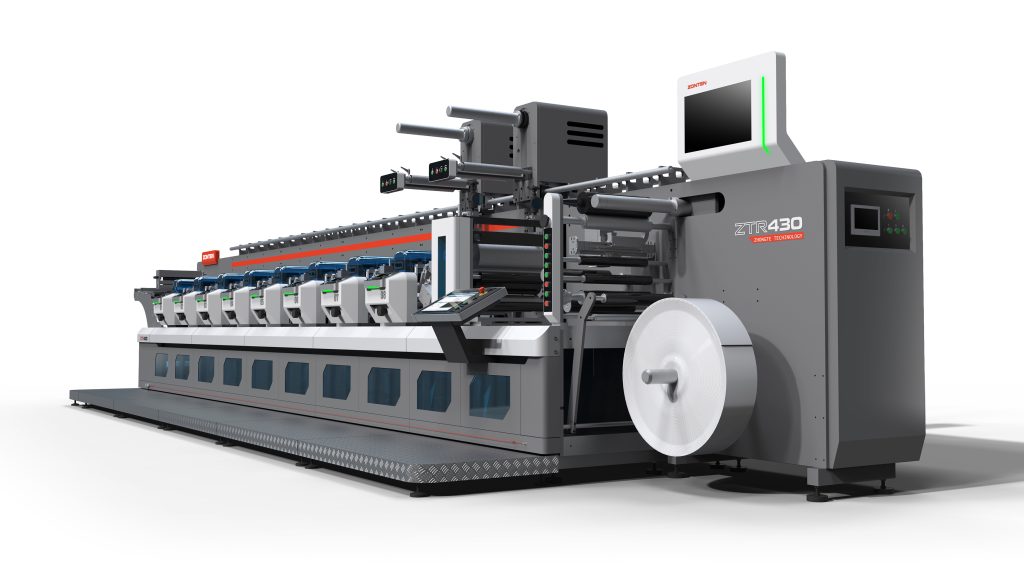

MATSET MATBAA MAKİNE VE MALZ. A.Ş. technical team successfully completed the installation of the first of the 3 ZONTEN ZTR-370 Flexo Printing Machines sold so far in Turkey and delivered it. AKTAŞ ETİKET, where the first ZONTEN ZTR-370 Flexo Printing Machine was installed, has achieved high level flexo printing quality and production performance in labels from roll to roll with this investment.

AKTAŞ ETİKET, which operates in Esenyurt and serves in the self-adhesive printed label sector with flexo printing systems, serves sectors such as food, beverage, cosmetics, chemistry, pharmaceuticals. AKTAŞ ETİKET continues its way confidently with the latest technology investments they have made in their machinery park with the capacity to produce approximately 4.000.000 m2 of labels per year by using flexo, embossing and hot foil printing techniques on all kinds of compact and laminated materials with its high-tech machine park and trained expert staff in its 1500 m2 closed area facilities.

Mr. Halil İbrahim Aktas from AKTAŞ ETİKET said that they preferred ZONTEN ZTR-370 Flexo Printing Machine as the best in terms of price and performance with its unique patented technologies and technical equipment, offering high quality and standards with the highest-level configuration content and that they were very satisfied with their decision as a result.

Mr. Halil İbrahim Aktas from AKTAŞ ETİKET said that they preferred ZONTEN ZTR-370 Flexo Printing Machine as the best in terms of price and performance with its unique patented technologies and technical equipment, offering high quality and standards with the highest-level configuration content and that they were very satisfied with their decision as a result.

In addition, MATSET MATBAA MAKİNE VE MALZ. A.Ş., which has effective infrastructure and technical service with its own electronic, mechanical and printing technicians in Turkey. As a solution partner in the long term, they are one step closer to the automation and digitalization they are aiming for, they have carefully examined each technology on the ‘ZONTEN ZTR-370’ and they have the idea of making the most of the printing, embellishment and finishing technologies available on the machine.

Orkun Kayal, Sales Manager of Matset Printing Machinery and Materials Analogue Printing Systems, summarised the most prominent advantages of the ZONTEN ZTR-370 Flexo Printing Machine installed at AKTAŞ ETİKET as follows;

• Short paper pass

• Full Servo; Each unit is driven by an independent servo motor. The whole machine uses 20 servo motors (in 8 colours) to ensure stable register at high printing speed.

• Shortest set-up time and minimum waste

• Easy and fast printing process with Pre-Register and Automatic Register

• One-pass printing, LED UV – UV drying, trimming and finishing

• Unique MULTIPRINT automation that ensures productivity and process repeatability

• Exceptional stable production quality over time

• Low maintenance and operating costs.