This famous quote by Justin Trudeau during his 2018 speech at Davos perfectly encapsulates the era we are living in. One where the pace of change – particularly technological change – is accelerating faster than we can truly imagine.

An opportunity? Or a threat? Change can be both. The worst thing to do in the face of a fast-changing environment is nothing at all. However, big traditional industries like the packaging industry are not always the quickest to embrace change and adopt new technology.

‘Industry 4.0’ has been discussed for several years, but digital transformation is still slow-going in many packaging companies. A McKinsey poll of global manufacturing companies found that only 26% said they had scaled some or many Industry 4.0 use cases.[i] The reason? In the packaging industry, many companies are still primarily focused on the short to medium term, and perhaps have concerns about the initial investment required to integrate new technology.

But we have reached an inflection point. Companies must think like start-ups – embrace change, and be flexible, quick to act, and agile.

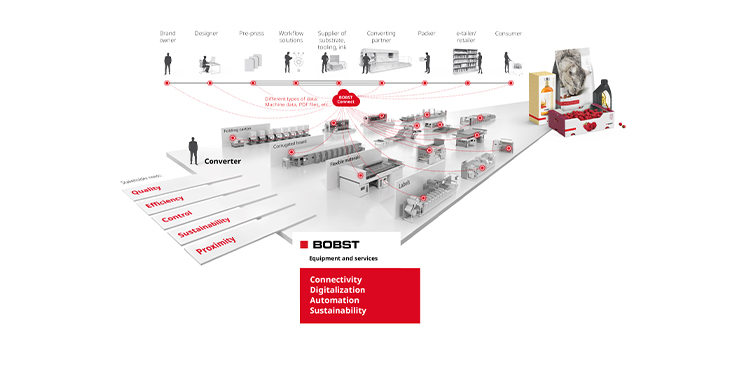

Below are five reasons why. And how BOBST – with our strategy built on the pillars of digitalization, connectivity, automation and sustainability – can help brand owners and converters to adapt to the new reality and future-proof their businesses.

1. Meet rapidly changing consumer tastes and priorities

The rise in technology has handed power to the consumer. In the past, brands had much more control. Packaging was standardized, batch sizes and time to market were more predictable.

With technology today, consumers have a voice to engage with brands and their peers. They want personalization, unique and memorable experiences. They want sustainability. And in the sea of consumer items, they want something new, which stands out, and speaks to them as a person.

Brand owners and converters have no choice but to keep pace with rapidly changing consumer tastes and priorities. This means shorter runs and shorter times to market. To be able to deliver this, they must embrace solutions with digitalization, connectivity and automation.

There are many BOBST solutions that make this a reality. For example, the MASTER M5 for labels and flexible packaging is built for full digitalization of the production workflow, the ultimate press for converters willing to automate their production line. Configurable with print cylinders or sleeves, the machine is ready to be equipped with oneECG technology delivering repeatable consistency run after run, irrespective of the application run length. It has high press uptime and enables very fast time-to-market.

Or take gravure, which has always been a clear choice for premium quality packaging but until now has been challenging for shorter print runs and faster delivery. BOBST’s smartGRAVURE – developed for the MASTER RS 6003 for flexible packaging – transforms gravure from a highly manual operation to a fully digitalized workflow. As set-up times are offline, machine downtime for preparation is significantly reduced. Printers can produce exceptional and consistent quality, while delivering orders quickly with high profitability, whether they are small, medium or long runs.

Shorter runs and rapid time-to-market are possible – all while maintaining the highest print quality.

2. Face global sustainability challenges head on

Environmental and sustainability issues are at the top of the agenda of governments, companies, and individuals all over the world. In the past, sustainability in packaging was a ‘nice to have’ – something to aspire to, but not necessarily a priority. No longer.

Major corporations have made bold sustainability pledges, which the packaging industry must now help to deliver. Sustainability has become a leading priority for consumers. At BOBST, as leaders in the packaging industry, we believe we have a responsibility to lead and innovate in this space and to help converters and brand owners meet sustainability targets.

That’s why we are reducing the environmental impact of future and existing packaging machines – for example, reducing energy consumption by 20% for the machines we will sell in 2030 vs our baseline of 2022. We are also improving equipment sustainability through reduction of ink, waste, and substrate. For example, oneECG – our extended color gamut technology, which digitalizes and automates color management – creates no ink waste, uses 30% less ink, and reduces make-ready time and make-ready waste by up to 90%.

We’re also helping to pioneer environmentally friendlier packaging. Together with leading industry partners, we have developed oneBARRIER, a range of innovative, industrially viable recycle-ready mono-material substrates as alternatives to non-recyclable multi-material film.

We’re also helping to pioneer environmentally friendlier packaging. Together with leading industry partners, we have developed oneBARRIER, a range of innovative, industrially viable recycle-ready mono-material substrates as alternatives to non-recyclable multi-material film.

And with our Competence Center facilities and R&D process experts we are helping brand owners, converters and industry partners by using our equipment and laboratories to develop their own solutions and meet their own company sustainability targets.

Tackling global environmental challenges may seem daunting, but there are steps that all brand owners and converters can take to rapidly improve the sustainability of their packaging.

3. Adapt to new workforce realities

There is a global skills shortage affecting converters, which will only become more pronounced. Traditional printing and packaging methods rely on skilled packaging technicians; a decade or two ago, you would find converters filled with skilled technicians who had made a lifetime career of their abilities. That is no longer the case. Workers trained on traditional printing technologies are retiring, and there are not enough trained technicians coming through the ranks to fill their places.

This trend increases the need for easy-to-use and automated machines. It increases the preference for all-in-one or one-pass printing solutions over multi-process solutions. Digital solutions will become more prominent, displacing conventional technologies and bridging the skills gap.

The DIGITAL MASTER series for labels is a good example, leveraging proven flexo approaches with recent innovative inkjet developments, providing a fully digitalized and automated production line from printing to embellishment and die-cutting, all coupled with inline quality inspection at full speed and automatic calibration thanks to BOBST ACCUCHECK system. Each print, embellishment and finishing module includes a high degree of digitalization and automation for exceptionally high uptime, low waste, high quality and outstanding repeatability regardless of the operator’s skills. But automation and digitalization alone are not enough; the real benefit is the fact that all modules are fully developed by BOBST and driven by one single piece of software, ensuring perfect synchronization.

Another example is oneSET, part of the smartGRAVURE package. Gravure traditionally relies on a manual set up process requiring high skill levels, however with oneSET, the system automatically suggests the most suitable and efficient machine settings based on the basic job parameters in the customer’s PDF file.

Another example is oneSET, part of the smartGRAVURE package. Gravure traditionally relies on a manual set up process requiring high skill levels, however with oneSET, the system automatically suggests the most suitable and efficient machine settings based on the basic job parameters in the customer’s PDF file.

Or the intelligent Metallizing Assistant, which represents a breakthrough in machine integrated process expertise for vacuum metallizing. It automates the deposition process, resulting in more output and consistency of the end product, while dramatically reducing required training time for operators.

It’s also important to stress that it is not a case of machines replacing the human workforce throughout the industry. Rather, changes in job descriptions and roles will create new and exciting opportunities for careers – for example those with training and expertise in digital and AI.

4. Future-proof businesses in the face of global uncertainty

The Global Peace Index states that the world has become less stable in the past 17 years with substantial increases in political instability, number of conflicts, and violent demonstrations.[ii] With a global pandemic in the mix too, we have been living through a period of significant uncertainty.

For the packaging industry, the uncertainty has led to a series of challenges, including hikes in raw material costs, disruptions to supply chains, and fluctuations in market demand.

In the face of uncertainty, converters need reliability – machines they can count on, connected to a partner with the abilities and reach to act quickly if support is needed. For example, BOBST’s remote assistance services, Helpline Essential and Helpline Advanced, ensure customers reduce machine downtime and save on repair costs. Connectivity enables provision of data to inform rapid decision making. Our three global distribution centers ensure optimal delivery times of spare parts.

BOBST also acts as a strategic partner for its customers. BOBST Application Management is a hands-on innovative consulting service, which is designed for the needs of converters and brand owners. Through BOBST Application Management, customers can receive guidance on technologies, raw materials, processes and business cases along the entire packaging value chain.

5. Maintain a competitive advantage and don’t get left behind

Competition in the packaging industry is fiercer than ever before. It’s vital that brand owners and converters stay ahead of industry trends and establish a competitive advantage.

The pillars on which BOBST built its global strategy in recent years—connectivity, digitalization, automation, and sustainability—have indeed emerged as global market trends in printing and converting. These pillars are now completely transforming the packaging value chain, from a series of isolated silos to a connected end-to-end overview. We are seeing a major acceleration of data usage from PDF to twin PDF, job recipe, machine learning, AI and using best information throughout the production workflow end to end. Embracing these pillars can help customers to address their pain points, gain a competitive advantage, and reach their targets.

At the heart of the transformation is BOBST Connect, our cloud-based digital platform that enables overview and orchestration of the production process, enhancing and improving the packaging productivity of our equipment. BOBST Connect is constantly evolving, and regularly introducing new functionalities helps secure investments and enhance productivity.

At the heart of the transformation is BOBST Connect, our cloud-based digital platform that enables overview and orchestration of the production process, enhancing and improving the packaging productivity of our equipment. BOBST Connect is constantly evolving, and regularly introducing new functionalities helps secure investments and enhance productivity.

Let’s embrace the change, together

Change can be daunting, but it is also exciting. Traditionally, the packaging industry has been slow to change, and it’s true that some of the older, traditional approaches still have value. But the world is changing, and the pace of change is increasing.

For example, we are only really at the start of the era of artificial intelligence (AI), and none of us truly knows where that will take us – but transformative change is happening all around us, at speed.

For companies to survive and thrive, it’s important to be a part of the change, to embrace it, and evolve as needed. For BOBST, we will continue to stay ahead of industry trends, embracing the new era of connectivity, digitalization, automation, and sustainability, and providing solutions that help our customers to stay ahead and maintain a competitive advantage. Remember, change has never been this fast. And it will never be this slow again.