Introduction: Printing inks are vital components in the world of graphic arts and printing. They play a crucial role in transferring images and text from the printing plate to various substrates such as paper, plastic, metal, fabric, and more. In this article, we will delve into the fascinating world of printing inks, exploring their types, composition, manufacturing processes, and diverse applications across industries.

Types of printing inks:

Types of printing inks:

Oil-based Inks: Oil-based inks, also known as letterpress inks, are one of the oldest forms of printing inks. They consist of pigments or colorants dispersed in a drying oil, such as linseed or soybean oil. Oil-based inks are commonly used in letterpress, offset lithography, and flexography.

Water-based Inks: Water-based inks, as the name suggests, use water as the main solvent. These inks are environmentally friendly and commonly used in applications where quick drying is not essential, such as newsprint, packaging, and flexographic printing.

Solvent-based Inks: Solvent-based inks utilize organic solvents as the carrier to dissolve the pigments or resins. They are widely used in high-speed printing processes, including gravure and screen printing. However, their volatile nature and potential environmental concerns have led to a decrease in their usage in recent years.

UV-curable Inks: UV-curable inks consist of liquid monomers and oligomers that polymerize rapidly when exposed to ultraviolet (UV) light. This curing process enables instant drying and results in a durable and high-quality print. UV-curable inks find applications in various fields such as packaging, labels, signage, and industrial printing.

Sublimation Inks: Sublimation inks are specially designed for sublimation printing, a process where the ink transforms from a solid to a gas under heat and pressure, bypassing the liquid state. This technique is commonly used for printing on textiles, ceramics, and other materials with a polyester coating.

Composition of printing inks:

Composition of printing inks:

Printing inks are complex formulations that consist of several key components:

- Pigments or colorants: These provide the desired color and opacity.

- Binders or resins: Binders act as a film-forming agent, holding the ink together and enabling it to adhere to the substrate.

- Vehicles: Vehicles are the liquid component that carries the pigments and binders, providing the ink with its flow properties.

- Additives: Additives are incorporated to enhance various ink properties, such as viscosity, drying time, adhesion, and color stability.

Manufacturing Processes:

The production of printing inks involves a series of steps, including dispersion, grinding, mixing, and quality control:

- Dispersion: In this stage, the pigments or colorants are dispersed in the liquid vehicle using specialized equipment to break down aggregates and achieve a uniform distribution.

- Grinding: The dispersed mixture is subjected to grinding to reduce particle size and ensure smooth ink flow. Bead mills or three-roll mills are commonly used for this purpose.

- Mixing: Once the pigments are finely ground, binders, additives, and other components are added, and the mixture is further homogenized using mixers or stirrers.

- Quality Control: The final ink formulation undergoes rigorous quality control tests, including color matching, viscosity measurement, pH testing, and printability assessment.

Applications of printing inks:

Applications of printing inks:

Printing inks find applications across a wide range of industries, including:

Publishing and commercial printing: Inks for newspapers, magazines, books, brochures, and other printed materials.

Packaging: Inks used for flexible packaging, cartons, labels, and corrugated boxes.

Textiles: Inks for textile printing, including garments, apparel, home textiles, and industrial fabrics.

Security printing: Specialized inks used for banknotes, passports, certificates, and other security documents.

Product Decoration: Inks for printing on consumer goods such as bottles, cans, packaging, and promotional items.

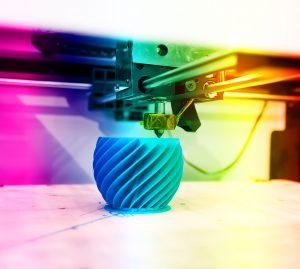

3D printing: Inks specifically formulated for additive manufacturing processes, enabling the creation of three-dimensional objects.

Printing inks are vital components of the printing industry, enabling the reproduction of text, images, and designs on various substrates. They come in diverse types, each with its unique properties and applications. As technology advances, printing inks continue to evolve, offering improved print quality, environmental friendliness, and enhanced durability. With their versatility and wide-ranging applications, printing inks continue to shape the world of visual communication and design.